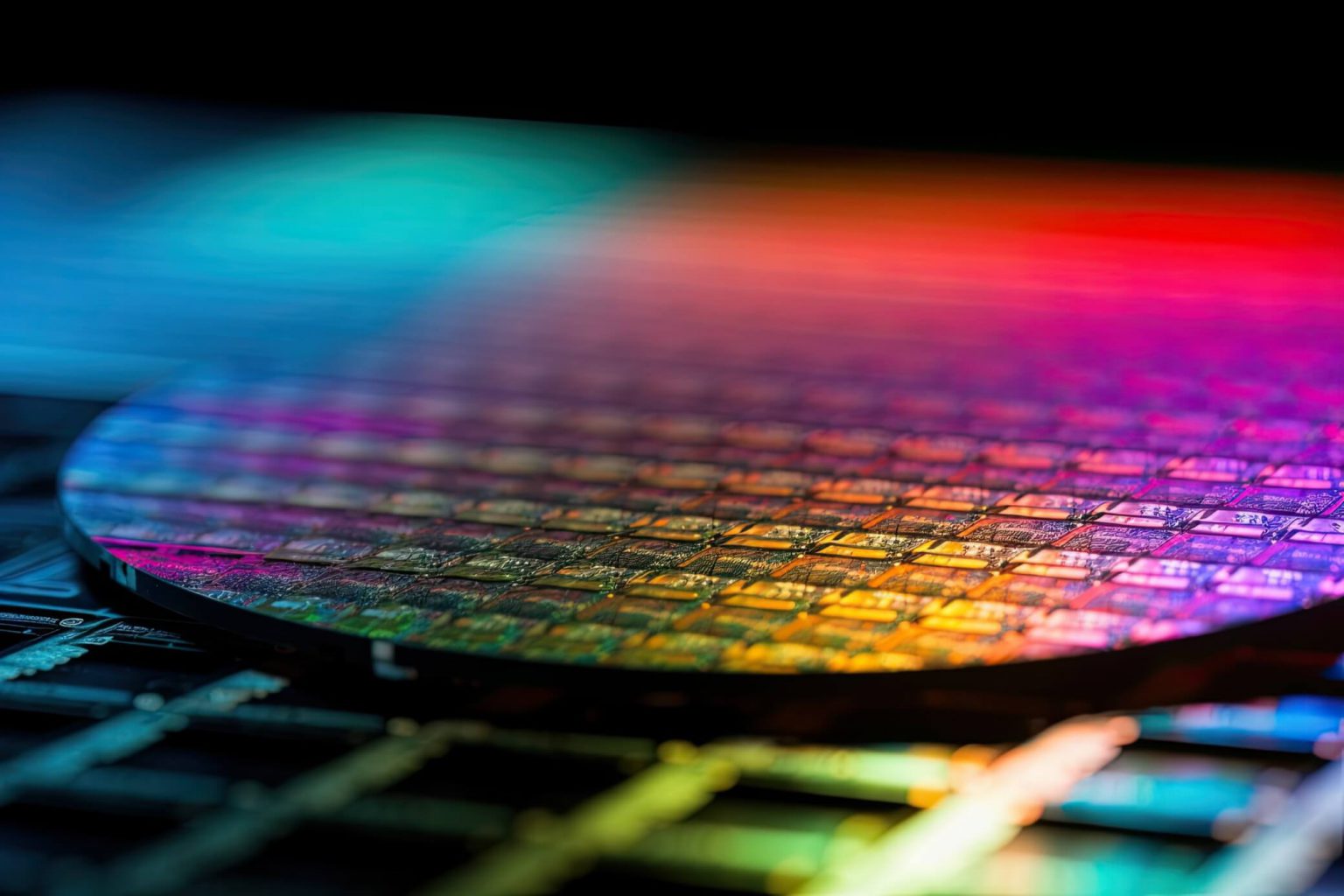

Transistors

Transistors are the building blocks of modern electronics, and at InnovaFlex Foundry, the hub where transistors, the fundamental components of modern electronics, undergo a transformation. Our focus is on pushing the boundaries of what is achievable. Our Transistor technologies take the lead in enabling energy-efficient, high-performance electronic devices.

In computing, communication, and the latest applications, we are committed to redefining the design and capabilities of transistors, fueling the advancement of technology. Our goal is clear at InnovaFlex Foundry: to develop top-notch TFT (Thin-Film Transistor) technologies in collaboration with the right partnerships.

In practical terms, we are not just theorizing; we are actively engaged in producing high-performing TFT technologies that will make a real difference in the field of electronics. Our emphasis on partnership underscores our belief that progress is a collective effort. At InnovaFlex Foundry, we are all about making advancements in transistor technology that count.

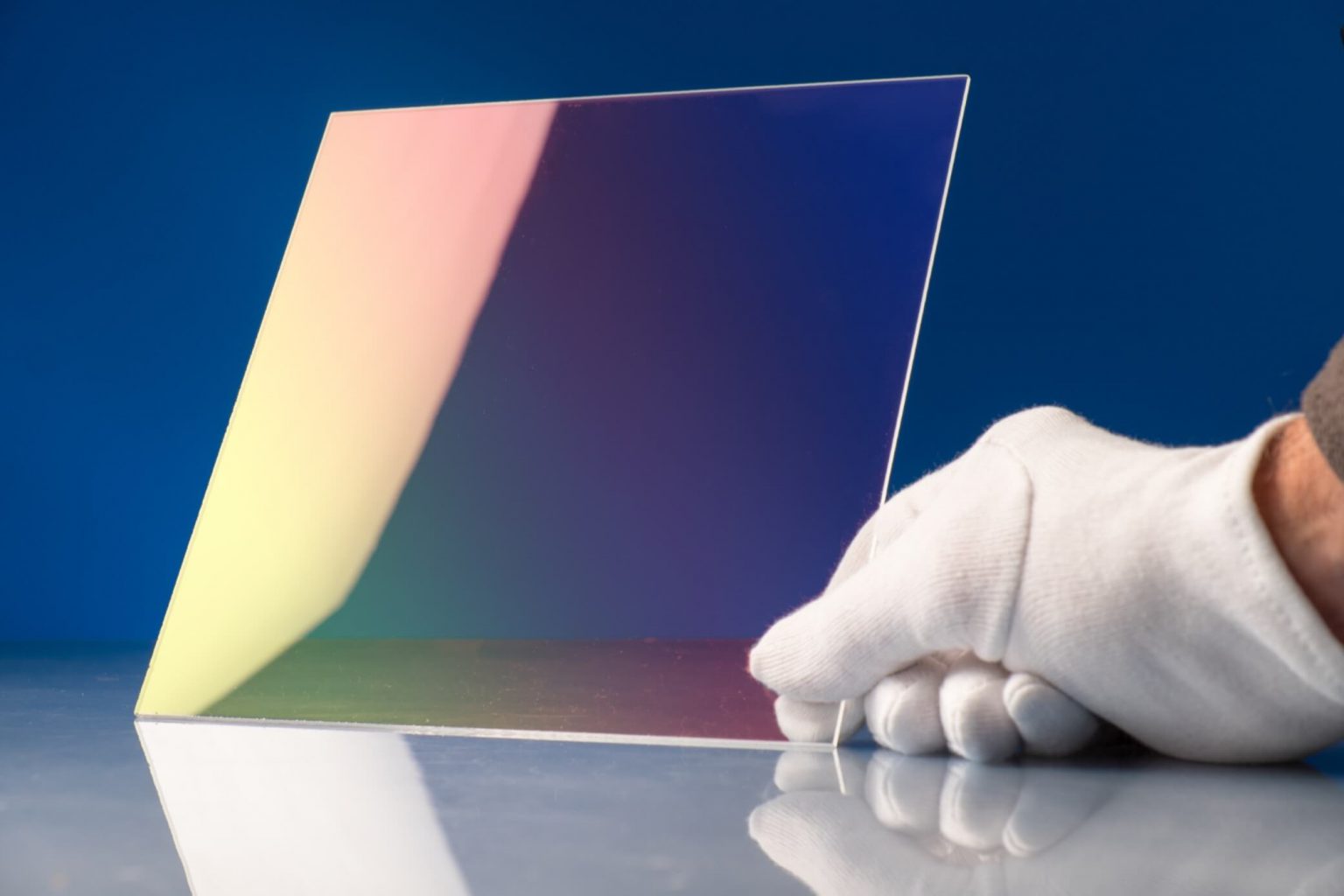

Oxides

Materials stand as the bedrock of innovation, and we embody this in our Oxide technologies. Our core expertise lies in tapping into the distinctive characteristics of oxides, crafting materials that become the launchpad for revolutions in electronics, energy storage, and beyond.

At InnovaFlex Foundry, not only do we unravel the intricacies of materials at an atomic scale, but we also possess the capability to deposit and pattern these materials on our glass and flexible substrates. It is not just about understanding and manipulating, but about practically applying these innovations.

InnovaFlex Foundry is not a mere observer in this journey; we are at the forefront of generating real-world applications and pioneering cost-efficiency in this realm. The Gen 4.5 FAB involves integrating these advanced materials into larger glass sheets, a move that aims to drive down costs without compromising on performance. Our commitment to pushing the envelope is reflected in our pursuit of excellence in oxide technologies.

Diodes

Diodes play a crucial role as current regulators in electronic circuits. InnovaFlex Foundry goes beyond conventional views, seeing diodes as drivers of transformative progress. Our Diode technologies offer industries precise current control, leading to improved energy efficiency, communication, and signal processing capabilities. These advancements are pivotal in shaping the trajectory of technology.

In addition, our capabilities expand further. At InnovaFlex Foundry, we not only manufacture diodes but also specialize in producing photo diodes, components that can capture light. What is more, we have the expertise to seamlessly integrate these photo diodes onto larger surfaces like glass sheets and flexible substrates, utilizing our Gen 4.5 FAB.

Our commitment is not just theoretical; it is practical. By pushing the boundaries of diode technology and facilitating their integration into broader applications, InnovaFlex Foundry is actively contributing to a future defined by innovation and real-world impact.

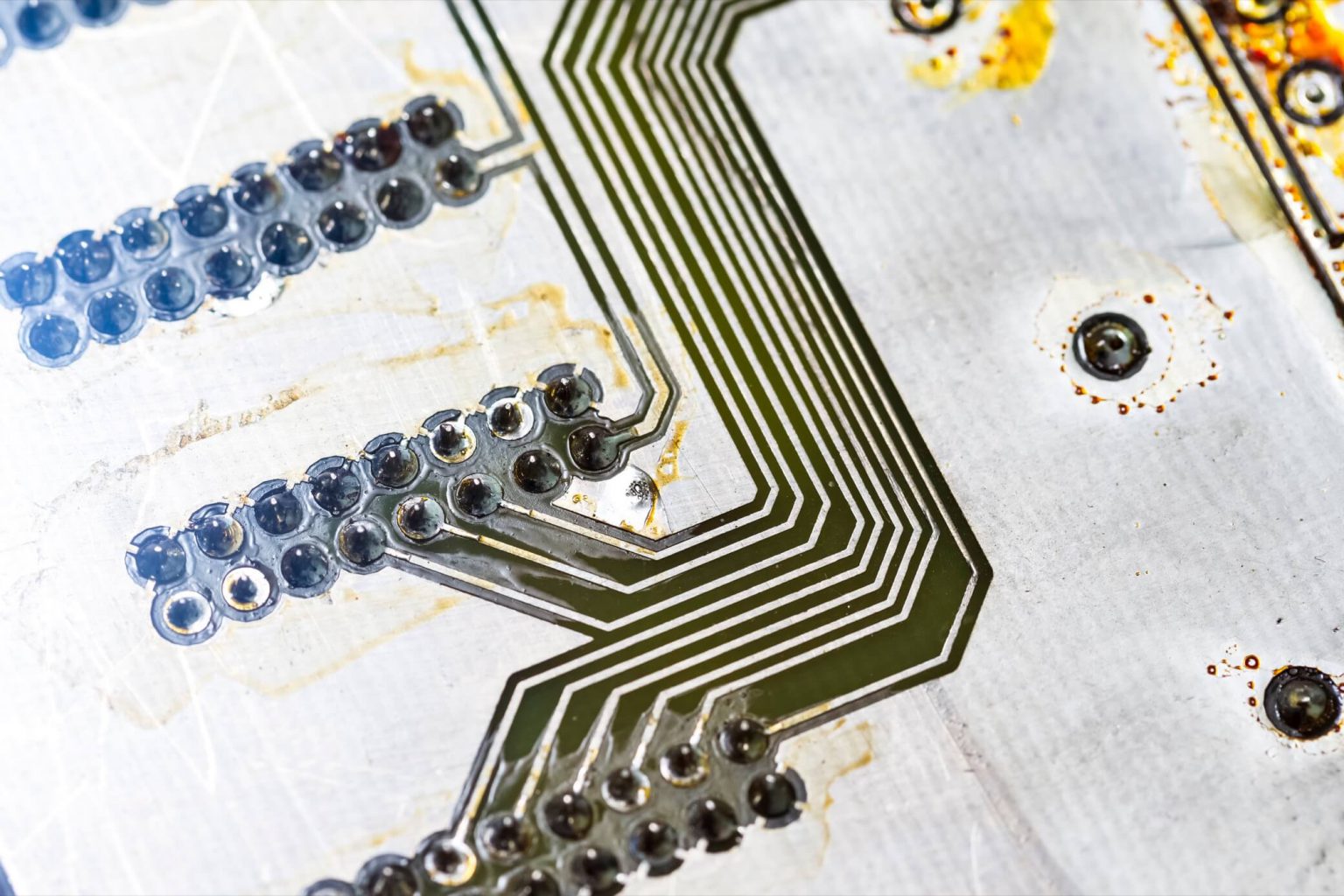

Metal Lines

Navigating the complex web of electronics, Metal Lines emerge as the vital conduits that shape connectivity. Within InnovaFlex Foundry’s scope, our aspiration reaches beyond mere functionality. We strive to forge Metal Lines that serve as more than just efficient signal carriers; they become enablers of groundbreaking design horizons. Our metal line technologies stand as architects of high-performance, dependable electronic ecosystems.

However, our capabilities extend beyond conceptualization. At InnovaFlex Foundry, we wield the ability not only to design these Metal Lines but also to deposit and structure them on broader canvases like glass and flexible substrates. This knack for precision allows us to integrate these pathways seamlessly into larger constructs.

Moreover, our Gen 4.5 FAB underscores our commitment to efficiency. By incorporating these Metal Lines into substantial sheets of glass, we are driving cost-efficiency without compromising quality. Our pursuit is not confined to isolated innovation; it spans practical integration and pragmatic solutions.

InnovaFlex Foundry’s dedication does not merely dwell in ideas; it is about tangible implementation. By redefining Metal Line possibilities and merging them with real-world applications, we are shaping a landscape where connectivity is not just functional—it is transformative.

Polymers

Polymers, like the versatile medium of a sculptor, hold the potential to shape the landscape of materials science. Our Polymer technologies are a bridge that spans diverse applications, stretching from the realm of flexible electronics to materials suited for medical compatibility. In our vision, polymers stand as the driving force behind innovation across sectors ranging from wearables to healthcare.

Within InnovaFlex Foundry’s precincts, we do not merely shape polymers; we also possess the proficiency to deposit and structure them, thus translating ideas into tangible constructs. The versatility of these polymers, when combined with precision engineering, yields breakthroughs.

Furthermore, our Gen 4.5 FAB propels us towards efficiency. By embedding these Polymer technologies into substantial glass sheets, our mission is to enhance cost-effectiveness while preserving quality. This step underscores our practical approach to innovation—a journey not confined to labs but etched into the fabric of industry realities.